How are Gold Coins Made?

01/05/2024Daniel Fisher

Free & fully insured UK Delivery. Learn more

Secure & flexible payments. Learn more

Buyback Guarantee Learn more

The very concept of exchanging coins to represent money requires faith in the value of the coins as a medium of exchange. For centuries, using gold to create coins provided the scarcity and perception of value needed to maintain their primary function.

While gold is no longer used for creating currency, gold bullion coins are still minted for investment and collectable markets. These sectors rely on the coins remaining consistent in their gold content and intricate craftmanship.

But have you ever wondered how gold coins are created? Understanding the journey of gold coins from sourcing and refining the precious metal, to designing and minting the final coin, reveals how each step is a testament to human ingenuity and dedication to excellence.

Coin minting refers to the process of manufacturing coins by stamping metal blanks with engraved dies to create the desired design and specifications. It involves the precise coordination of machinery and skilled labour to produce coins that meet quality standards and regulatory requirements.

Minting encompasses various steps, including preparing the metal blanks, striking them with the designed images, and inspecting each coin for consistency and integrity. This process is crucial in ensuring the production of coins that are recognizable, durable, and suitable for circulation or collection.

Gold coins are typically produced by government-operated mints or private mints licensed by government authorities. Government mints, such as the United States Mint or the Royal Canadian Mint, are responsible for minting legal tender gold coins for investment purposes, that carry the official stamp and backing of the issuing government. These mints adhere to strict standards of quality and security to ensure the integrity of the coins they produce.

However, the primary focus of these mints is to produce base metal coins for circulation and use as everyday currency. The production volume of gold bullion coins is minute compared to the minting of currency coins. The use of gold in circulating coins receded in the 1930s when the gold standard ended, so now precious metals are only used to create bullion coins.

Private mints, on the other hand, may also produce gold coins, but they do not have the authority to issue legal tender. Instead, they often create niche gold coins for investment or commemorative purposes, adhering to industry standards and regulations. Regardless of the minting authority, the production of gold coins involves a meticulous process to ensure each coin meets the required specifications for purity, weight, and design.

The UK’s Royal Mint traces its origins back over a thousand years, with its roots dating to the late 8th century during the reign of King Offa of Mercia. However, it became officially established as an institution in 886 AD when Alfred the Great of Wessex consolidated various mints under royal control.

The government-owned entity operates under the ownership of Her Majesty’s Treasury in the United Kingdom. While it operates as a business entity, it is ultimately accountable to the UK government and operates according to regulations set by Her Majesty’s Treasury. It’s reptation for excellence means the Royal Mint also produce a limited number of coins for other countries.

In the UK, they are primarily entrusted with;

The Royal Mint is responsible for producing coins and currency for the United Kingdom. It manufactures circulating coins, commemorative coins, and bullion coins, as well as producing coins for other countries around the world under contract.

The Royal Mint is involved in the distribution of coins and currency throughout the United Kingdom. It ensures that an adequate supply of coins is available to meet the demands of commerce and banking.

Free ultimate guide for keen precious metals investor

The starting point in the entire process is sourcing gold to use in the manufacturing of coins. While there’s no official record of where their gold supply comes from, the Royal Mint states that all its gold comes from London Bullion Market Association (LBMA) approved sources. It adheres to responsible sourcing practices and may participate in initiatives promoting ethical gold production and transparency in the supply chain. Some of these may include;

The Royal Mint may purchase gold directly from mining companies that extract and refine the precious metal. These companies operate gold mines around the world and supply gold to the market for various uses, including coin production.

Bullion banks act as intermediaries between gold producers, refiners, and consumers. They may provide gold to the Royal Mint through purchase agreements or trading on the open market.

The Royal Mint may also obtain gold from accredited refiners that produce investment-grade gold bars and coins. These refiners adhere to strict quality standards to ensure the purity and authenticity of the gold they produce.

Additionally, the Royal Mint may recycle gold from various sources, including old or damaged coins, jewellery, and industrial scrap. This recycled gold can be refined and reused in the production of new coins.

Refining gold is a crucial process in preparing the precious metal for coin production. It involves several key steps:

The first step in refining gold is melting it down to a liquid state. This is typically done in a furnace at high temperatures, where the gold is heated until it reaches its melting point of 1,064 degrees Celsius (1,948 degrees Fahrenheit).

Once melted, impurities such as dirt, dust, and other metals rise to the surface and can be skimmed off, leaving behind purified gold, which forms the basis for making the coins. A sample of this molten metal is then appraised to verify the composition and purity are correct.

Pure gold is often too soft to be used in coin production, so it is commonly alloyed with other metals to increase its strength and durability. Common gold alloying metals include silver, copper, and nickel. The proportions of these metals are carefully measured to create an alloy that meets the required specifications for coin production.

Royal Mint Britannia gold coins are now made from 999.9 purity gold, while the famous Sovereign gold coin consists of 916.7 purity gold, with the alloy now solely comprising copper. Older Sovereigns contained additional elements of silver and traces of iron or tin.

After alloying, the liquid gold is poured into a holding furnace where it gradually cools so it can be rolled into a 16mm thick continuous strip which is wound into a giant gold coil weighing 2.5 tonnes.

A heavy roller is then used to reduce the thickness initially to 3mm and then further down to the the required depth of the coins on a finishing mill.

This rolling process prepares the thickness of the gold while maintaining its strength and uniformity. The resulting gold sheets are ready to be cut into blanks for coin production.

The final step in refining gold involves cutting the rolled sheets into precise blanks of the desired size and shape for coin production. This is typically done using specialized machinery that ensures each blank meets the required specifications.

These gold blanks serve as the starting point for the coin striking process, where they are stamped with the desired design and specifications to create the finished coins.

Designing gold coins is a meticulous and controlled process that involves several key steps. The timescale required for consultation and designs necessitates the process to start well in advance of the minting schedule.

Coin designs are often chosen based on historical significance, cultural symbolism, or commemorative themes. They may also feature iconic national symbols, important figures, or significant events. The selection process typically involves input from artists, historians, and government officials to ensure that the chosen designs reflect the intended message or theme of the coins.

While a mint’s core coin designs are enlisted to renowned illustrators and sculptors, they sometimes try to engage with the public on more niche coins by inviting them to submit designs. The Royal Mint, for example, held a design competition for the 2012 London Olympic Games Gold £5 Proof coin.

The winning design was created by a talented individual named David Lawrence, which was then adapted by the Royal Mint’s engravers to create the final image. His design, titled “The Fragment Design,” was praised for its innovative interpretation of the Olympic Games and its striking visual appeal.

Once a design concept is chosen, the coin design process begins. Artists create detailed drawings or digital renderings of the proposed design, taking into account factors such as size, shape, and composition. These drawings serve as the blueprint for the coin’s final design.

After the design is finalized, it’s translated into three-dimensional form through various methods. Artists may create large-scale clay models or plaster casts of the design to capture its intricate details and textures. These models are then used to create reduction models, which are smaller-scale replicas of the design known as “masters.”

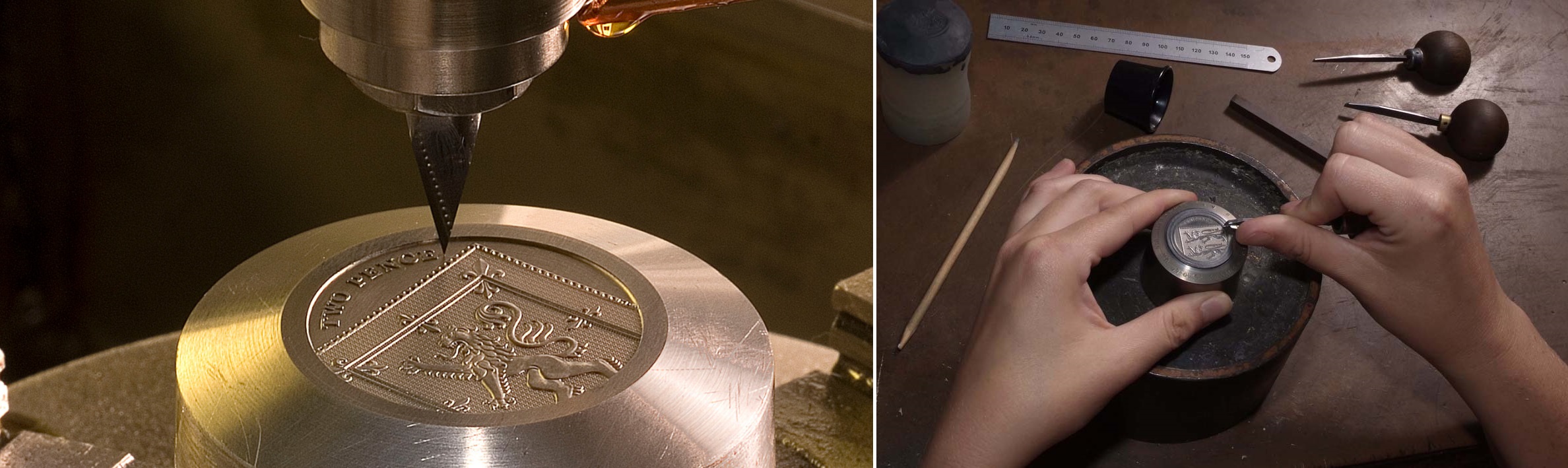

From the masters, specialist machines create “reduced size” models known as “hubs.” These hubs are then used to make “incuse” dies, which are the negative image of the coin design. These incuse dies are used to strike the coin blanks, transferring the design onto them during the striking process.

Throughout this process, precision and attention to detail are paramount to ensure that the final coin design accurately reflects the intended vision and meets the standards of quality and authenticity required for coin production.

The coin design process will combine the creativity of renowned artists with a strict design brief.

The exciting part comes next. Striking the gold coins, also known as minting or coining, requires a precise and intricate process that involves several key steps:

Flat pieces of metal are cut to the desired size and shape to create gold blanks.

The gold blanks are placed between two engraved dies, one representing the obverse (front) and the other the reverse (back) of the coin.

The dies are carefully aligned to ensure that the design is centred and properly oriented on the coin blank.

Using a coining press, immense pressure is applied to the dies, causing them to stamp the design onto the gold blanks.

The pressure from the coining press creates raised images and inscriptions on the surface of the coin, transferring the design from the dies onto the gold blank.

The optimal balance of precision and pressure ensures that the design is transferred onto the gold blank with clarity and accuracy, resulting in well-defined coin images.

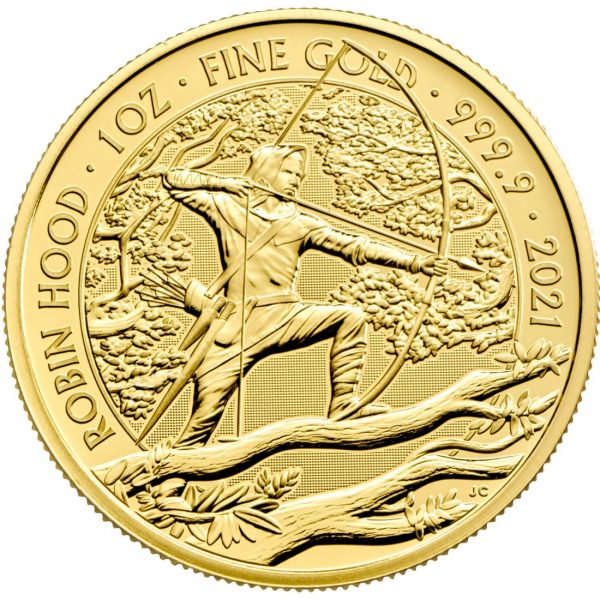

Gold coins are struck in various finishes, each catering to different preferences and purposes. The minting process varies slightly according to which finish the mint are seeking.

Proof coins are struck using specially polished dies and blanks, resulting in a mirror-like finish and sharply defined details. They are often produced with extra care and attention to quality, making them highly sought after by collectors. The enhanced aesthetics produced with this process are accompanied by a higher price tag and limited mintage numbers. We often describe the finish of proof coins to be like comparing Ultra High-Definition TV with Standard Definition.

BU coins are struck using standard production methods and typically have a lustrous finish with crisp details. They are intended for general circulation or collection and are often packaged in protective capsules or folders.

Bullion coins are struck primarily for their precious metal content and are not intended for numismatic purposes. They may have a simpler design and finish compared to proof or BU coins but are valued for their intrinsic gold content and are commonly traded as investment assets. They’re cheaper to mint and are mass-produced, so command lower gold premiums for their investment buyers.

Our automated portfolio builder will provide suggestions based on various investment objectives

By implementing stringent quality control methods, addressing mint-made errors transparently, and applying appropriate finishing techniques, the Royal Mint ensures that each gold coin produced meets the highest standards of quality and craftsmanship. Maintaining the quality of gold coins involves several important aspects:

Quality control methods are employed throughout the coin production process to ensure that each coin meets established standards. These methods may include visual inspections, weight checks, and measurements of diameter and thickness. Additionally, advanced technologies such as laser scanning, and X-ray fluorescence may be utilized to detect any irregularities or defects in the coins. Generally, any defective coins, sometimes known as wafflers, are rejected and returned to refineries.

Despite rigorous quality control measures, some mint-made errors can occasionally escape inspectors’ eyes. These errors may include issues such as off-centre strikes, double strikes, or planchet errors. While these errors are relatively rare, they can result in coins with unique characteristics that are sought after by collectors. The Royal Mint acknowledges these errors and may release them to the public as collectible items.

After the striking process, gold coins undergo finishing processes to enhance their appearance and protect their surfaces. Finishing techniques may include frosting or polishing the surfaces of the coins to create contrast between the raised and recessed areas of the design. Additionally, coins may be treated with protective coatings or lacquers to prevent tarnishing and preserve their lustre over time.

Preserving the quality and ensuring the availability of gold coins involves two main aspects:

Preserving the condition of gold coins is essential to maintain their value and appeal over time. Preservation methods include storing coins in protective capsules or holders to prevent damage from scratches, abrasions, or exposure to air and moisture. Additionally, storing coins in a controlled environment with stable temperature and humidity levels can help prevent tarnishing and degradation of the metal. While Royal Mint used to sell bullion coins in plastic blister packs, they have largely been phased out and replaced with official coin tubes. The adhesive used in the blister packs was sometimes unreliable, causing coins to move around.

Once gold coins are cleared for sale, they are distributed and sold direct through official mint websites or authorized dealers, such as PhysicalGold.com. Distribution channels may include, as well as through auctions, coin shows, and numismatic exhibitions. The Royal Mint also partners with banks and financial institutions to make gold coins available for purchase and investment.

Gold coins are typically not made of pure gold. Most gold coins are alloyed with other metals such as silver, copper, or nickel to increase durability and strength. The purity of gold coins is measured in karats, with 24 karat gold being the highest purity. Common gold coin alloys range from 22 karats to 91.67% pure gold.

Gold coins are made from refined gold obtained through mining and purification processes. The gold is melted and poured into moulds to create uniform gold blanks. These blanks are then struck with engraved dies to imprint the desired design and specifications onto the surface of the coin.

Refining gold is crucial to ensure the purity and quality of gold coins. It involves removing impurities and alloying the gold with other metals to improve its durability and strength. This process ensures that the gold coins meet the required standards for purity and authenticity.

Coin designs are chosen based on various factors, including historical significance, cultural symbolism, and commemorative themes. Design concepts are often submitted by artists and selected through competitions or internal review processes. The chosen design is then adapted and refined to create the final coin.

The coin striking process involves stamping gold blanks with engraved dies to create the desired design and specifications. This process requires precision and pressure to ensure that the design is transferred onto the surface of the coin with clarity and accuracy. The striking process is essential to produce well-defined and detailed gold coins.

Image credits: PXHere, Royal Mint

Live Gold Spot Price in Sterling. Gold is one of the densest of all metals. It is a good conductor of heat and electricity. It is also soft and the most malleable and ductile of the elements; an ounce (31.1 grams; gold is weighed in troy ounces) can be beaten out to 187 square feet (about 17 square metres) in extremely thin sheets called gold leaf.

Live Silver Spot Price in Sterling. Silver (Ag), chemical element, a white lustrous metal valued for its decorative beauty and electrical conductivity. Silver is located in Group 11 (Ib) and Period 5 of the periodic table, between copper (Period 4) and gold (Period 6), and its physical and chemical properties are intermediate between those two metals.