The Physical Properties of Platinum

30/08/2024Daniel Fisher

Free & fully insured UK Delivery. Learn more

Secure & flexible payments. Learn more

Buyback Guarantee Learn more

Platinum, often referred to as one of the most precious and sought-after metals, is arguably the third best known metal for jewellery use after gold and silver. Certainly, platinum is sometimes perceived by many as the superior choice to gold when it comes to items such as wedding bands. While its price has historically been higher than that of gold’s, in recent years the yellow metal’s value has surpassed that of platinum due to safe-haven demand.

Platinum’s rarity, combined with a remarkable set of physical properties, makes it invaluable in various industries—from high-end jewellery to critical applications in the automotive and medical fields. In this article, we’ll shed light on why this silvery-white metal is so revered and why platinum is considered a wise choice for precious metals investors.

Platinum is a dense, malleable, and ductile metal with a striking silver-white appearance. Known for its remarkable resistance to corrosion and tarnish, platinum is one of the least reactive metals, making it highly valuable in both industrial and decorative applications. This precious metal is found naturally in the Earth’s crust and is often extracted from deposits alongside other metals like nickel and copper.

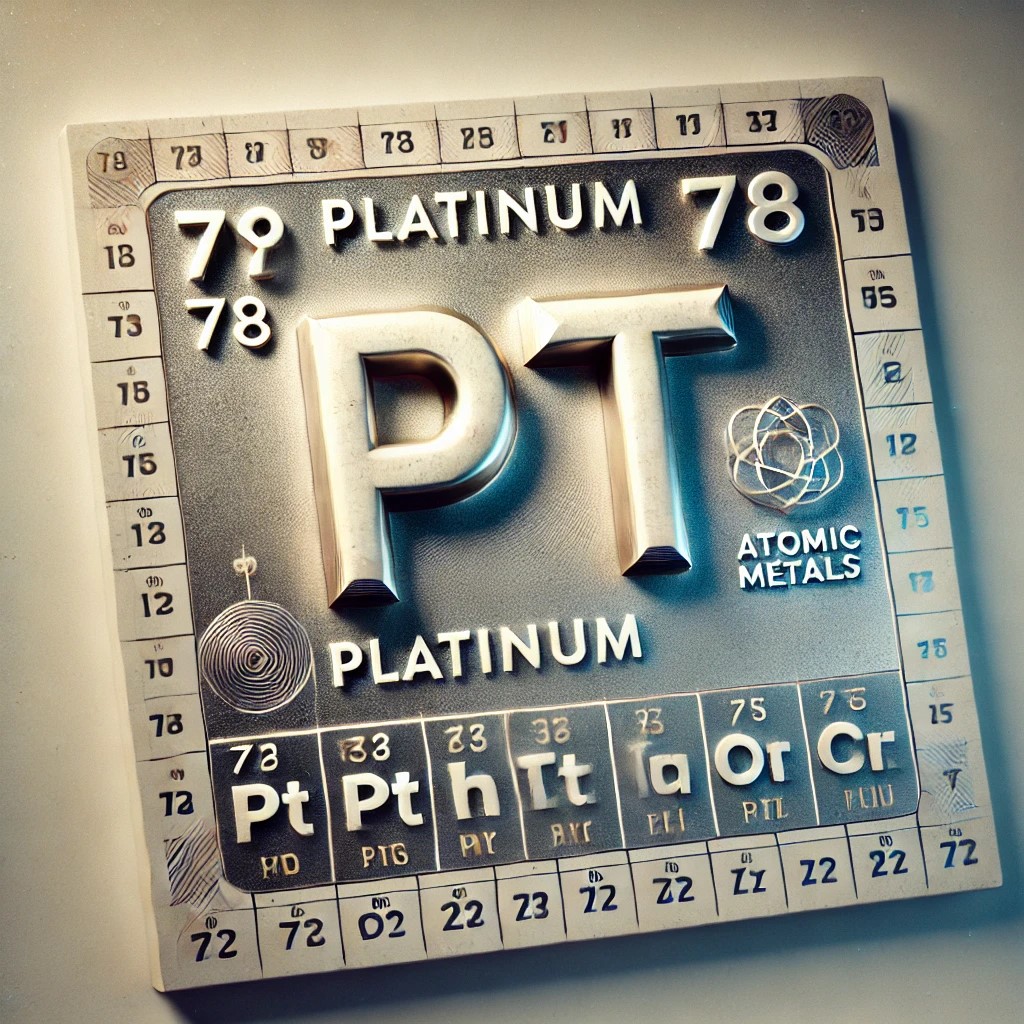

Platinum is represented by the chemical symbol “Pt” on the periodic table. It belongs to group 10 and period 6, nestled among other transition metals such as nickel and palladium. Its position on the periodic table reflects its characteristics as a heavy, noble metal with high resistance to chemical reactions. All striking similarity to gold’s traits.

The atomic number of platinum is 78, which indicates that it has 78 protons in its nucleus. This atomic number places platinum in the same neighbourhood as other noble metals, known for their exceptional stability and resistance to corrosion. The atomic structure of platinum, with its fully filled d-orbitals, contributes to its unique properties, including its strength and unreactive nature.

Platinum is classified as a transition metal, a category that includes elements known for their ability to form various oxidation states and complex compounds. As a transition metal, platinum plays a vital role in industrial chemistry, particularly as a catalyst in reactions that require a stable and unreactive medium. Its ability to facilitate chemical processes without undergoing significant changes itself is what makes platinum indispensable in industries ranging from automotive to electronics.

Platinum is renowned not only for its rarity and durability but also for its distinct and appealing physical appearance. In the luxury jewellery sector platinum plays a crucial role in providing a more upmarket option to customers who prefer the look of silver jewellery to gold.

Consumer preference will always be split between those who prefer the yellow hue of gold, and individuals who opt for the more subtle jewellery colour that platinum provides.

Platinum’s structure creates a more resilient and long-lasting option to silver jewellery, which is why it’s such a popular choice for wedding band rings.

Platinum boasts a lustrous silver-white colour that gives it a sophisticated and timeless aesthetic. Unlike silver, which can tarnish over time, platinum maintains its bright, reflective surface with minimal care, making it ideal for high-end jewellery and decorative items. Its cool, neutral tone complements a wide range of gemstones and other metals, enhancing its appeal in the design world. It’s perceived as a far less ostentatious look than gold.

Yes, platinum is highly reflective. This property is one of the reasons why it is prized in both ornamental and practical applications. Old platinum rings can be professionally polished by jewellers to make their appearance as reflective and shiny as new.

In addition to its use in jewellery, platinum’s reflective qualities make it valuable in scientific instruments and mirrors where a high degree of reflectivity is essential. Its ability to reflect light also contributes to the metal’s radiant appearance, making it a standout choice for pieces meant to endure through generations.

One of the most striking physical characteristics of platinum is its density. Platinum has a density of approximately 21.45 grams per cubic centimetre, making it one of the heaviest metals, beating its main competitor gold which possess a density of 19.32g/cm3. This high density gives platinum a substantial, weighty feel that is often associated with luxury and quality. The metal’s density is also a factor in its durability, contributing to its resistance to wear and deformation under stress.

Platinum is both highly malleable and ductile, meaning it can be easily shaped and drawn into thin wires without breaking. Compared to gold and silver, platinum is more challenging to work with due to its hardness, but this also means it holds its shape better over time. Platinum can be hammered into thin sheets or twisted into fine wires, making it versatile for intricate designs in jewellery. Despite being tougher than gold, it’s still more malleable than many other metals, allowing craftsmen to create detailed, long-lasting pieces.

Platinum is not only prized for its aesthetic qualities but also for its exceptional strength and durability. These properties make it one of the most reliable and enduring materials used in various demanding applications, from fine jewellery to industrial components.

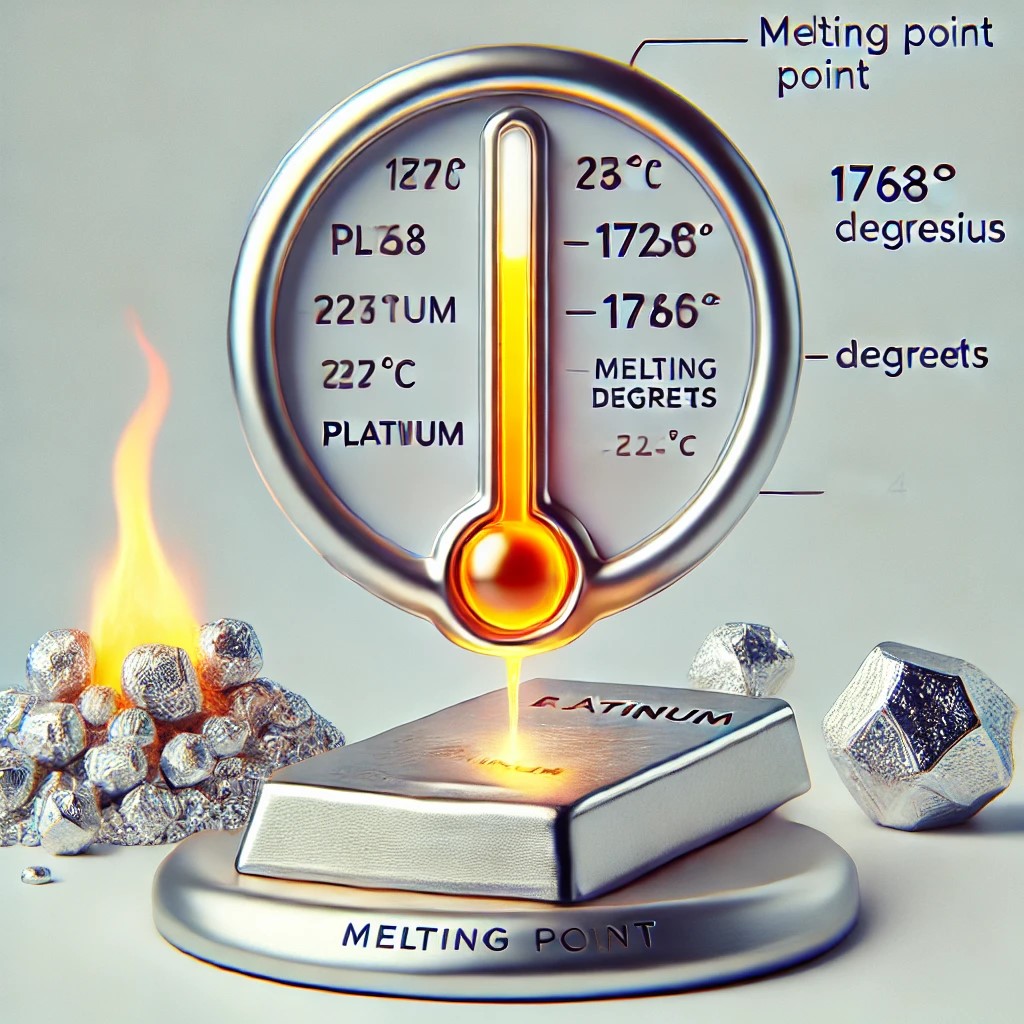

Platinum has an exceptionally high melting point of 1,768 °C (3,214 °F) and an even higher boiling point of 3,825 °C (6,917 °F). These extreme temperatures underline platinum’s stability under heat, making it ideal for use in environments where other metals would melt or degrade.

In industrial applications, such as in the manufacturing of high-temperature equipment or catalytic converters, platinum’s ability to withstand intense heat without losing its integrity is invaluable.

Platinum is relatively hard, with a rating of 4 to 4.5 on the Mohs scale of hardness. While not as hard as some metals like tungsten or titanium, platinum’s hardness is sufficient to resist significant wear and tear, making it highly durable for everyday use. This rating is almost twice gold’s rating of 2.5, and significantly higher than silver’s Mohs score of 2.8. This makes platinum more difficult to manipulate for jewellery, but more resilient.

This hardness, combined with its dense structure, also contributes to its impressive scratch resistance. Unlike gold, which can be easily scratched and worn down, platinum maintains its smooth surface even after years of use, especially in jewellery. Its durability ensures that platinum pieces, whether in jewellery or industrial components, retain their form and functionality over time.

While many common gold coins add metal alloys to improve scratch resistance, Platinum bullion coins tend to be at least 999.5 fineness, due to the metal’s superior resilience.

No, platinum is not magnetic. Unlike ferromagnetic metals such as iron, nickel, and cobalt, platinum does not attract magnets and does not exhibit magnetic properties. This non-magnetic nature makes platinum useful in applications where magnetic interference could be an issue, such as in certain electronic devices or in scientific instruments. The absence of magnetism also adds to its stability in various chemical environments, further enhancing its reputation as a versatile and reliable material.

Call our team on 020 7060 9992 for availability and options

Platinum’s chemical assets are as impressive as its physical attributes, making it a metal of choice for many specialized applications. Known for its remarkable stability and resistance to chemical reactions, platinum is often classified as a “noble metal” due to its ability to withstand corrosion and oxidation. These properties not only make platinum valuable in everyday items like jewellery but also crucial in scientific and industrial processes.

One of the most notable chemical properties of platinum is its exceptional resistance to corrosion. Unlike many other metals that can tarnish or degrade when exposed to air, moisture, or harsh chemicals, platinum remains virtually unaffected. This is in stark contrast to it’s jewellery look-a-like silver, which despite appearing similar to platinum, tends to tarnish quite quickly.

This corrosion resistance is a result of platinum’s stable atomic structure, which prevents it from reacting with oxygen and forming oxides on its surface. This property makes platinum ideal for use in environments where long-term exposure to corrosive substances is common, such as in medical implants, chemical processing equipment, and automotive catalytic converters. Additionally, platinum’s ability to resist corrosion ensures that it retains its lustre and structural integrity over time, even under challenging conditions.

Platinum is renowned for its low reactivity with most elements, further solidifying its status as a noble metal. It does not react easily with oxygen, acids, or alkalis, which is why it is so durable and resistant to chemical wear. However, platinum can act as a catalyst in chemical reactions, meaning it can facilitate reactions without being consumed in the process. This catalytic property is particularly valuable in the automotive industry, where platinum is best-known for being used in catalytic converters to reduce harmful emissions. While demand for these mechanisms soared with increasing environmental awareness, it will likely go ‘full-circle’ as the increase in electric vehicles dispels the need for them altogether.

Platinum’s ability to catalyse reactions is also utilized in the production of various chemicals, including fertilizers, pharmaceuticals, and silicone. Despite its general resistance to reactivity, platinum can be dissolved in aqua regia (a mixture of nitric and hydrochloric acid), though this is one of the few substances capable of breaking down platinum.

While pure platinum is highly valued for its unique properties, it is often alloyed with other metals to enhance certain characteristics or adapt it for specific applications. This way platinum’s strengths can be utilised, while adding other metals can tweak its overall composition to tailor its performance for certain needs.

Alloying involves mixing platinum with other metals to create a material that combines the best attributes of each component. This process can affect platinum’s colour, hardness, and durability, making it more versatile for both industrial and decorative purposes.

Each precious metal tends to be best suited to coupling with certain other metals. For example, while gold is commonly alloyed with silver and copper, platinum is teamed with its own usual suspects. Common platinum alloys are iridium, ruthenium, palladium, and cobalt. Each of these metals brings different qualities to the alloy:

Platinum-Iridium

Iridium is added to platinum to increase its hardness and strength. This alloy is often used in scientific instruments, electrical contacts, and fine jewellery where durability is essential.

Platinum-Ruthenium

Ruthenium enhances the hardness and wear resistance of platinum, making this alloy ideal for applications requiring a highly durable material, such as in electrical components and in medical devices.

Platinum-Palladium

Palladium is frequently alloyed with platinum to create a lighter, more malleable alloy. This combination is often used in jewellery, where the metal’s bright, white colour and ease of workability are prized.

Platinum-Cobalt

Adding cobalt to platinum improves its magnetic properties and hardness, making it useful in certain types of industrial applications, such as in magnets and some high-performance engineering components.

Alloying platinum with other metals can significantly alter its physical and chemical properties, depending on the intended use. For instance, adding iridium or ruthenium increases the alloy’s hardness, making it more resistant to scratches and deformation. This is particularly beneficial in creating durable jewellery and industrial parts that must withstand heavy wear.

In contrast, adding palladium to platinum enhances its malleability and reduces its weight, making the alloy easier to work with for intricate designs and detailed craftsmanship. However, alloying can also slightly alter the colour of platinum, depending on the metals used, which is an important consideration in jewellery design.

Interestingly, some alloys can affect platinum’s magnetic properties, as seen in platinum-cobalt alloys, which are used in applications requiring controlled magnetic responses. Finally, alloying can influence platinum’s melting point and thermal conductivity, which can be advantageous in specific industrial processes where precise control over these factors is necessary.

Free ultimate guide for keen precious metals investor

Platinum is renowned not only for its strength, durability, and resistance to corrosion but also for its excellent thermal and electrical conductivity. These properties make platinum an essential material in various high-tech applications where efficient heat and electricity transfer are critical. Whether in electronics, medical devices, or industrial processes, platinum’s ability to conduct heat and electricity reliably and consistently is a key reason for its widespread use.

Platinum has a high thermal conductivity of around 70 W/m/K, which means it can effectively transfer heat. This property is particularly useful in applications that require stable and efficient heat management, such as in laboratory equipment, thermocouples, and high-temperature furnace components.

Platinum’s ability to conduct heat evenly and reliably helps ensure the accuracy and performance of these devices. Additionally, its thermal stability means that platinum can withstand significant temperature variations without losing its shape or function, making it ideal for use in environments where precise temperature control is crucial.

In addition to its thermal conductivity, platinum also possesses excellent electrical conductivity. Although it is not as conductive as metals like copper, silver, or gold, platinum’s electrical conductivity is highly valued in applications where durability and resistance to corrosion are just as important as efficient electricity transfer. For instance, platinum is often used in electrical contacts and connectors where a reliable connection must be maintained over long periods, even in harsh environments. It doesn’t try to compete with silver’s use in generic, budget electricals components, due to its higher price and lower conductivity rating.

The metal’s ability to maintain its conductive properties under extreme conditions makes it a preferred choice in aerospace, automotive, and telecommunications industries, where performance and reliability are critical. In more common applications, other metals are commonly preferred. While platinum is now less than half the price of gold, it is also 30 times rarer, meaning it’s mass-usage is limited.

Gold is more conductive than platinum, with gold having about 70% the conductivity of copper, while platinum has around 16%. Despite lower conductivity, platinum is valued for its durability and corrosion resistance, making it ideal for applications where long-term reliability is crucial, such as in high-performance electronics and industrial components.

Platinum is much rarer than gold, with annual production being about 15 times less. While gold is mined in large quantities worldwide, platinum is found in only a few regions, making it significantly scarcer. If all the platinum ever mined were melted, it would fill just over one Olympic-sized swimming pool, while gold would fill more than three.

Approximately 250 million ounces (about 7,100 metric tons) of platinum have been mined throughout history. Platinum is far rarer than gold, with only a small amount produced annually. Current global platinum reserves are estimated at 70,000 metric tons, making it one of the scarcest precious metals on Earth.

Platinum is a dense, malleable, and ductile metal with a silver-white appearance. It is highly resistant to corrosion, tarnish, and high temperatures. Known for its excellent conductivity and catalytic properties, platinum is used in jewellery, industrial applications, and electronics. Its rarity and durability make it one of the most valuable precious metals.

Live Gold Spot Price in Sterling. Gold is one of the densest of all metals. It is a good conductor of heat and electricity. It is also soft and the most malleable and ductile of the elements; an ounce (31.1 grams; gold is weighed in troy ounces) can be beaten out to 187 square feet (about 17 square metres) in extremely thin sheets called gold leaf.

Live Silver Spot Price in Sterling. Silver (Ag), chemical element, a white lustrous metal valued for its decorative beauty and electrical conductivity. Silver is located in Group 11 (Ib) and Period 5 of the periodic table, between copper (Period 4) and gold (Period 6), and its physical and chemical properties are intermediate between those two metals.